Tag: news

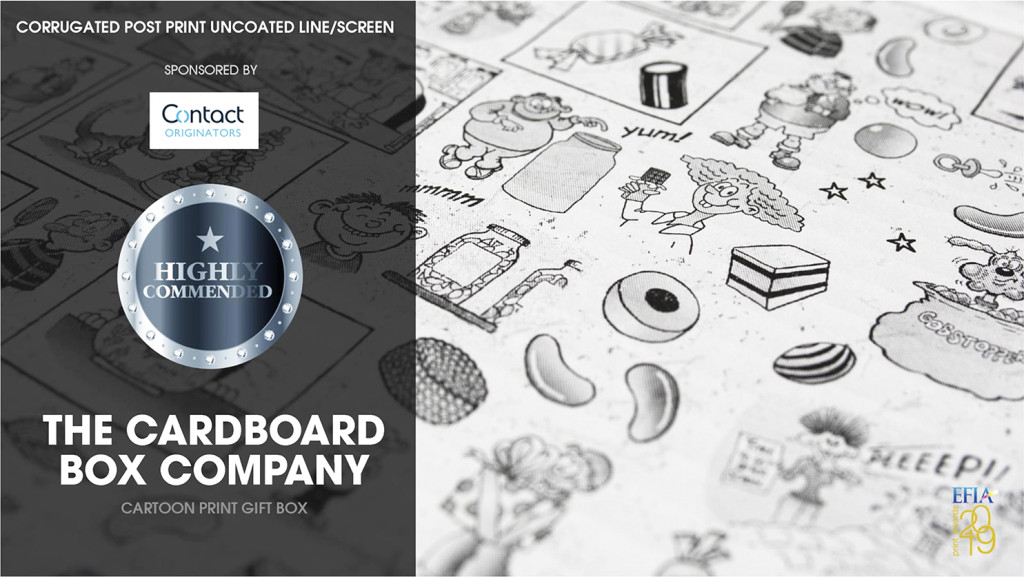

HIGHLY COMMENDED

Corrugated post print uncoated line/screen

Cartoon Print Gift Box

This printed box epitomised everything that this category required. The multiple illustrations on the print includes fine lines, dots and fine tone work printed at minimal tolerances on the Bobst 1624.

Due to the complex fine print, the anilox and print pressure had to be exact and the ink viscosity had to be monitored throughout the run to maintain the print quality.

The job was printed on a B flute 125g White Kraft.

We are pleased to announce that Logson Group, the UK’s largest independent supplier of corrugated packaging, have completed the acquisition of the Cardboard Box Company.

The Cardboard Box Company has a turnover of more than £17m and is one of the UK’s best invested sheet plants, with 90 employees. The Logson Group is a UK-based group of corrugated packaging companies. Collectively the Group employs over 1000 people with a turnover in excess of £200m.

Peter Street, The former owner, commented; “I have great trust in the Logson team to guide the business on the next stage of the journey. They know us well and understand the culture we have worked so hard to develop. I look forward to supporting the business in an ambassadorial role.”

Alex Kelly, CEO of Logson Group added; “Having courted Peter for many years, we are delighted to have finally acquired, what we believe, is one of the UK’s finest sheet plants. The business is well positioned to meet the increasing demands of key high growth sectors including Home Retail, FMCG and POS.”

Ken Shackleton, Managing Director at the Cardboard Box Company, who will continue to lead the business, commented; “This is a great fit for our business, the Logson approach will allow us to maintain our identity and entrepreneurial flair, backed by the financial strength and scale of the UK’s largest independent corrugated packaging group. We have exciting plans for our business moving forward and this move can only enhance our offering to both new and existing customers.”

The Cardboard Box Company will continue to operate as a stand-alone brand within the Logson Group, joining sister brands of Board24, Boxes and Packaging, Cases24, Boxshop and Jardin Corrugated. Collectively they form a unique mix of companies offering a full range of corrugated packaging solutions from 18 locations across the UK.

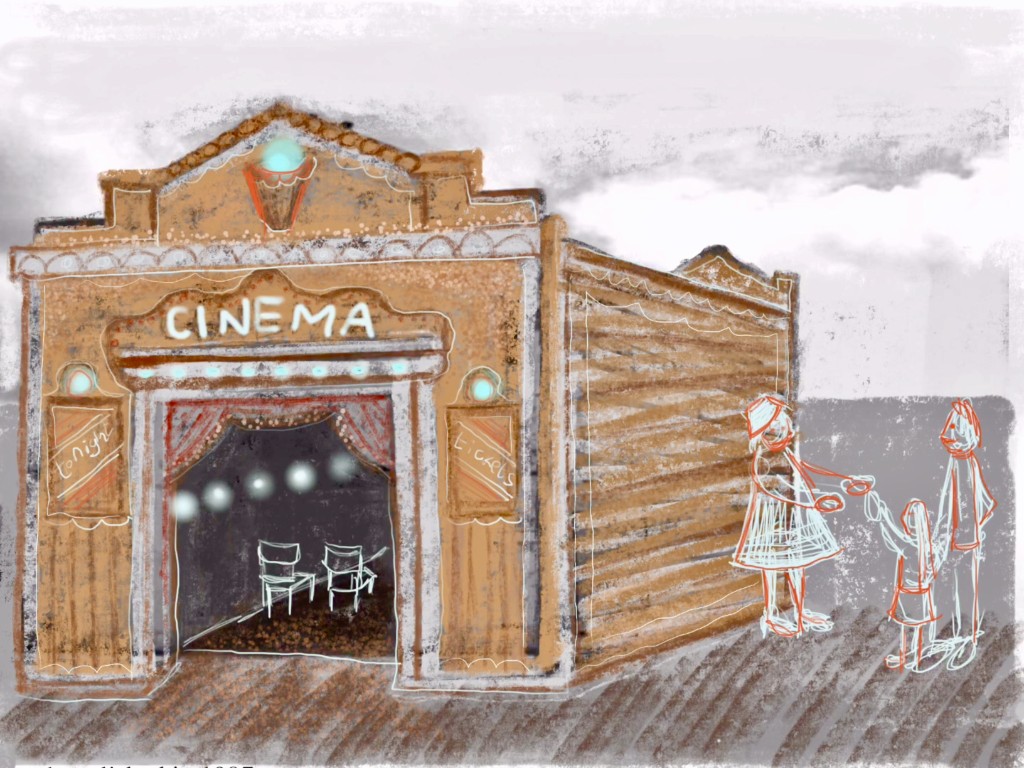

Hannah Fox and The Cardboard Box Company 2018

CBC worked alongside artist Hannah Fox of www.hannahonthehill.co.uk as part of the second ever Festival of Making in Blackburn town centre.

Embracing cardboard’s innate flexibility and constructional value and methods usually preserved for the development of industrial and retail packaging design.

With the capacity to design, print and manufacture cardboard boxes we collaborated with Hannah to design and build a cardboard cinema to reflect on Blackburn’s past as home to no fewer than 15 cinemas to recall a valuable, shared social history at risk of being forgotten.

Photo taken by GS Visuals

Art in Manufacturing – The National Festival of Making & Super Slow Way

GOLD Use of digital as a complimentary process

The project was to create a pub door effect light box that opens up to display a bar scene that has images lit up with LED backlights.

Fluorescent inks were used printed on our Bobst 618 machine to create parts of the images. The artwork was created and printed on our digital print machine. The CAD design was created so the doors can open and close to create the effect. LED lights were positioned around the image with a layered construction to create the 3D effect.

BOBST Digital Print Inspection Table

In October 2017 we became the first site in the world to take delivery of a pioneering Digital Inspection Table from BOBST.

Designed to enhance print quality control and virtually remove production errors, the Digital Inspection Table is a novel technology that incorporates digital projection for the proofing of printed sheets and die-cut blanks, whilst providing real-time visual representations to match product with digital proofs.

Ken Shackleton, Managing Director: “The Digital Inspection Table is a wonderful piece of British manufacturing that complements our print investment perfectly. We have invested in some truly fantastic assets over the past year that are already having a significant impact on the success of our business. The Digital Inspection Table takes us to another level in terms of quality and customer satisfaction.”

Developed by BOBST, in collaboration with innovation partner, HE Inventions, the Digital Inspection Table uses HD projectors to illuminate the product sample with quality control imaging, enabling the operator to easily see if quality standards are matched or compromised.

In addition, the layout file can also be projected on to the sheet so that print registration can be checked and adjusted, removing the need for overlays and print minis and moving the process from paper to digital.

In August 2017 we purchased a new high quality 6 colour print press

The acquisition of the Bobst 1624 NT means we can compete at the highest level of flexo printing on to boxes.

The six colour press allows anilox rollers to be interchanged within minutes to maximise print quality on different substrates.

The high graphics ability of this machine allows the production of shelf ready packaging and POS displays printed onto coated liners with a gloss finish.

Lazerian and The Cardboard Box Company 2017

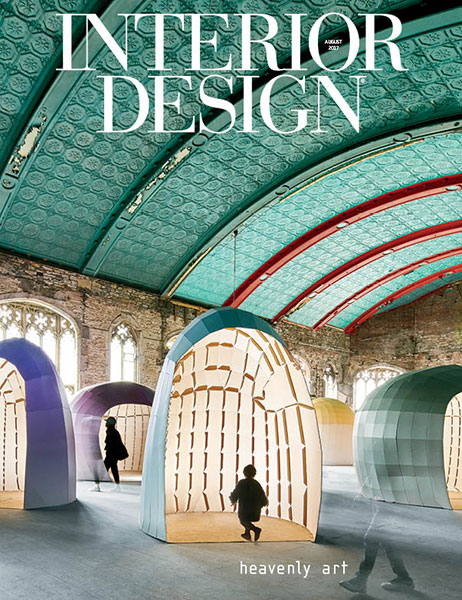

CBC worked alongside the artist Liam Hopkins from Lazerian at the first ever National Festival of Making in Blackburn in 2017. This resulted in an amazing and incredible piece of cardboard artwork which was recognised internationally, appearing on the front cover and centre pages of the New York INTERIOR DESIGN Magazine.

During his residency Lazerian’s founder, Liam Hopkins, discovered that the workforce of the Cardboard Box Company depended entirely upon each other – yet they worked largely alone, in distinct sectors. His vibrant and exotic cardboard structures evoke this modern predicament of individual detachment, whilst suggesting the colleagues’ essential connectivity. The pods’ use of irregular and organic forms presents a further challenge to perceptions by skewing the expected, strictly angular form of the cardboard box. And this is not to mention Chromatogram’s exuberant colour schemes – a direct result of Hopkins’ research into the company archives of colour palettes. Each tone in the range has been used by the manufacturer at some stage in its production history and their realisation in the work represents a record of the company’s stunning gradient of colour through time.

Art In Manufacturing 2017

A co-commission between the National Festival of Making and Super Slow Way, Art in Manufacturing was a groundbreaking set of commissions that paired 10 exceptional artists with Pennine Lancashire’s leading manufacturers. The incredible outcomes of their residencies were shown in Blackburn town centre’s most historic and contemporary venues as part of the 2017 National Festival of Making, produced and directed by Wash Design with supported by Creative Lancashire.

In April 2017 we purchased a second folder-gluer machine.

The Bobst EXPERTFOLD 165 is an extremely versatile folder-gluer which allows us to produce an impressive number of box styles in a wide range of materials at speeds of up to 450 meters per minute.

With complete control during the folding process, advanced feeding, accurate prebreaking and a folding process that minimises fishtailing and gap ensure high productivity and a quality finished product.

With its straight line, crash-lock, 4 & 6-corner capabilities and quick setting times, our EXPERTFOLD also provides the versatility and flexibility needed to meet whatever request you might have.

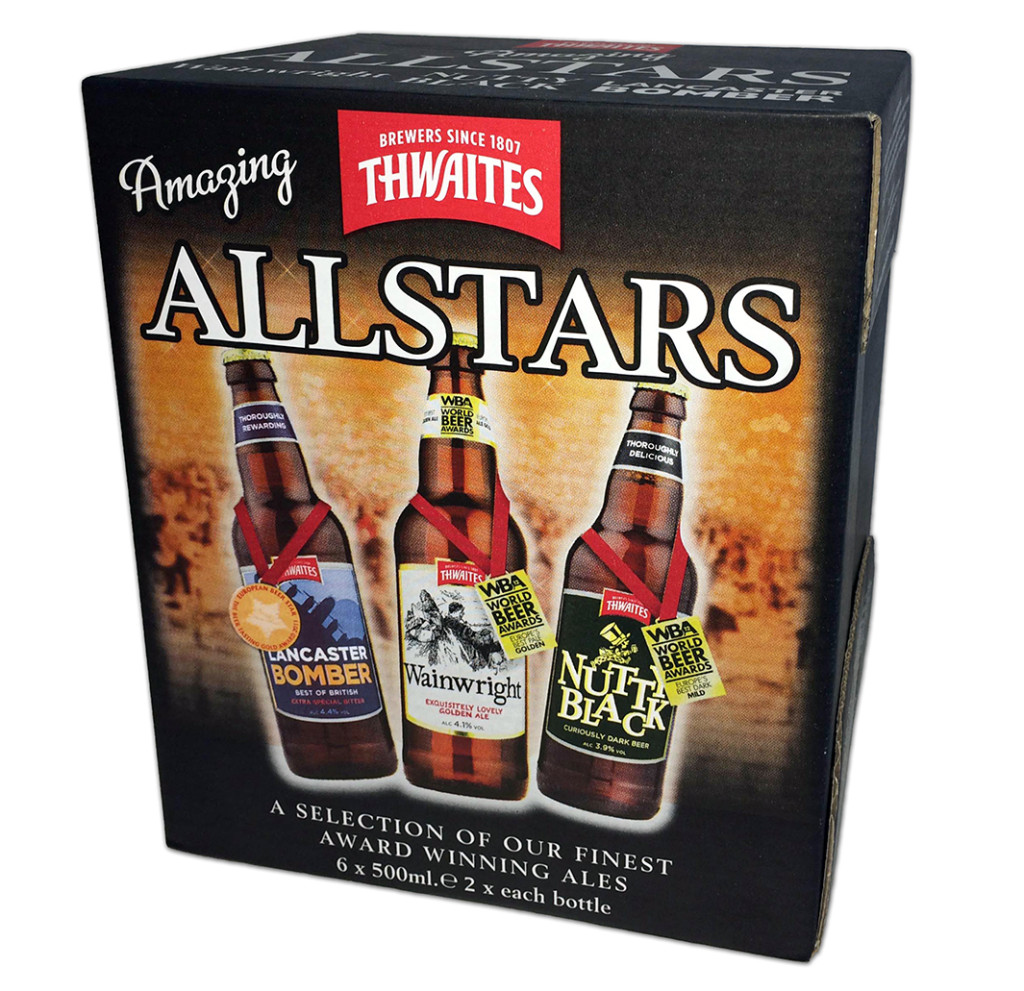

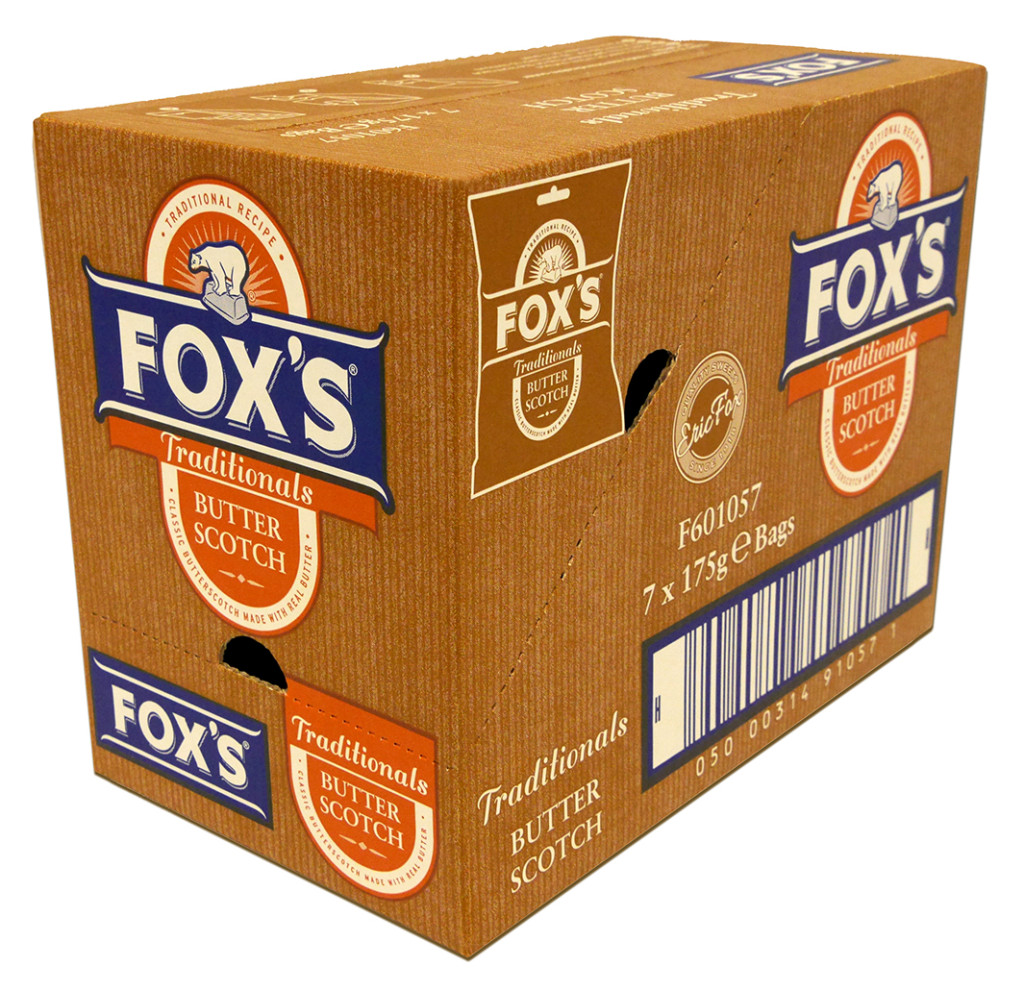

GOLD Post Print on Folder Gluers Uncoated

The artwork was supplied by a Design Agency as a 4 colour process suitable for litho print.

The challenge was to duplicate the litho artwork and convert this to be printed flexo.

All text, logos and the backgound image had to be Repro’d to the machine tolerances, this included Photoshop flexo re-touching of the photographic images including removing unnecessary colour from specific channels, grey component replacement, and minimum dot allowance.

The box was printed 4 colour and die-cut on our Bobst 618 casemaker rotary die cutter at 85 Lpi onto uncoated board in one pass.

GOLD Best Creative Use Of The Flexo Process

SILVER Post Print on Folder Gluers Uncoated

GOLD Best Creative Use Of The Flexo Process

We created a light box from corrugated board showing illuminated Halloween images by using fluorescent inks and LED lights.

The Halloween images were digitally printed onto corrugated board and made into a light box frame. Using our Bobst 618 press, we printed a number of boards in various colours using Fluorescent inks which would illuminate when LED light is used.

The Halloween images on the digitally printed frame were cut using our Zund G3 CAD cutting table. We cut the images from the various fluorescent boards and placed them behind the cut out areas on the frame. LED lights were placed around each image inside the frame to create the completed light box.

SILVER Post Print on Folder Gluers Uncoated

We were asked to create artwork for an SRP trying to match the same graphics as the product packaging which was printed Litho.

This type of work would normally be produced on larger complex printers which can achieve tight tolerances for registration .

We managed to create the artwork using only three colours, and had to use the minimum tolerances that were achievable on the machine and anilox specification.

The box was printed and die-cut on our Bobst 618 casemaker rotary die cutter at 75 Lpi onto uncoated board in one pass.