Tag: awards

This week on the 15th September we will be incredibly proud to celebrate 50 years in business!

What an achievement!

It was in 1999 that the business became The Cardboard Box Company but the story started long before then.

It was in 1975 when Chapman Industries formed Chapman Cartons to make and supply cardboard boxes to its five envelope manufacturing sites across the UK.

At that time, Chapman Envelopes was the largest envelope manufacturer in the UK so having its own box making factory to despatch its products made perfect sense.

It quickly became established, and it was recognised from the beginning that the success of the business depended upon its ability to offer credible solutions to customers’ packaging dilemmas. It’s an ethos that’s stayed pretty much the same across the decades.

In the 80s and 90s as the business gathered pace CBC had some pretty notable achievements; in the ‘80s, they designed the original satellite dish packaging for BskyB (British Sky Broadcasting) while in the ‘90s, Time Computers, the largest manufacturer of PC’s in the UK, supplied the first complete Home PC package to the UK retail market via Tesco in a box designed by them.

After several factory moves across the area the business settled in Accrington in 1989 and has stayed there ever since apart from an extension or two!

In was in 1999 that Trelleborg, its then owners, sold Chapman Industries and Chapman Containers and the latter was bought by a private businessman, Mr Peter Street.

With a new owner and a new name of The Cardboard Box Company, the business grew exponentially and increased its turnover significantly, until it was acquired by Logson Group in June 2018.

Today, the business operates a turnover of £24m with a clear plan to take this to £45m and maximum capacity at its current plant by 2029.

Some of our team have been here for many years including Daniel Johnston, Managing Director and Commercial Director, Matt Herd who joined the business around the same time, early in the new millennium.

Daniel commented; “I can’t quite believe where the time has gone since 2003 and the roles I have done since joining as a Cost Estimator when I finished Uni and didn’t really have a master career plan!

“I never planned to work in corrugated, and I accepted the job on a night out after my friends Dad offer me a post. I’d finished Uni and didn’t know what to do so it seemed sensible. Clearly it was the right thing to do!”

Matt added; “It’s quite unusual for people to stay with businesses for such a long time now however there is something quite unique about CBC. From joining in summer 2000, I have also worked in many different roles and know the business inside out.

“It’s a great place to be and I’m looking forward to taking the business forward and into its sixth decade with the rest of the team.”

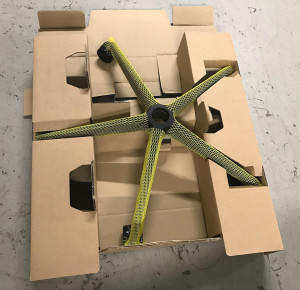

SILVER STAR AWARD

TRANSIT / INDUSTRIAL / DISTRIBUTION

Allermuir ECOFlex Chair Pack

This pack was required to be as small as possible, to save on space and increase container export payload, be neat and quick to assemble. The ease and the speed at which the fitting can be assembled is what makes it special. The one-piece design, with its simple folds, create adequate buffers with simple locking methods that prevent damage in palletised transit and whilst the pack is being handled. The slots create excellent location points to hold the chair parts exactly in place without any movement.

An environmental and cost saving benefit of the design was the removal of any need for polystyrene. The buffers created in the board, gives the box enough cushioning to fully protect the chair through transit. All parts support each other, with the added advantage of great strength, removing the risk of failure whilst in highly stacked export containers.

Judges’ Comments

“Very well designed pack for a product that is notoriously difficult to pack. Well thought through and good use of materials. Attention to positioning of the hand holds is required.”

Packaging Designer: Kristian Howson

Brand Owner: Allermuir (The Senator Group)

HIGHLY COMMENDED AWARD

TRANSIT / INDUSTRIAL / DISTRIBUTION

Blade Lighting Packaging

One common, corrugated pack solution to transport nine possible light combinations (three different lighting systems and three different lengths) utilising a cradle system with common width and height, which can be changed in length by locating two dividers in the correct position, offers the advantage of minimal tooling outlay. The cradle with its double walled sides and base struts allows for the product to be lifted up and away from the outside edges of the packaging with a final piece of packaging placed on top to protect the face of the lighting system.

The one-box solution, made from 80% recycled corrugated board is fully recyclable and delivers amazing flexibility and product protection delivering tangible cost and material saving efficiencies.

Judges’ Comments

“Easily accessible and a great material choice for a variable size pack.”

Packaging Designer: Marc Stobbs

Brand Owner: ACDC

HIGHLY COMMENDED

Corrugated post print uncoated line/screen

Cartoon Print Gift Box

This printed box epitomised everything that this category required. The multiple illustrations on the print includes fine lines, dots and fine tone work printed at minimal tolerances on the Bobst 1624.

Due to the complex fine print, the anilox and print pressure had to be exact and the ink viscosity had to be monitored throughout the run to maintain the print quality.

The job was printed on a B flute 125g White Kraft.

GOLD Use of digital as a complimentary process

The project was to create a pub door effect light box that opens up to display a bar scene that has images lit up with LED backlights.

Fluorescent inks were used printed on our Bobst 618 machine to create parts of the images. The artwork was created and printed on our digital print machine. The CAD design was created so the doors can open and close to create the effect. LED lights were positioned around the image with a layered construction to create the 3D effect.

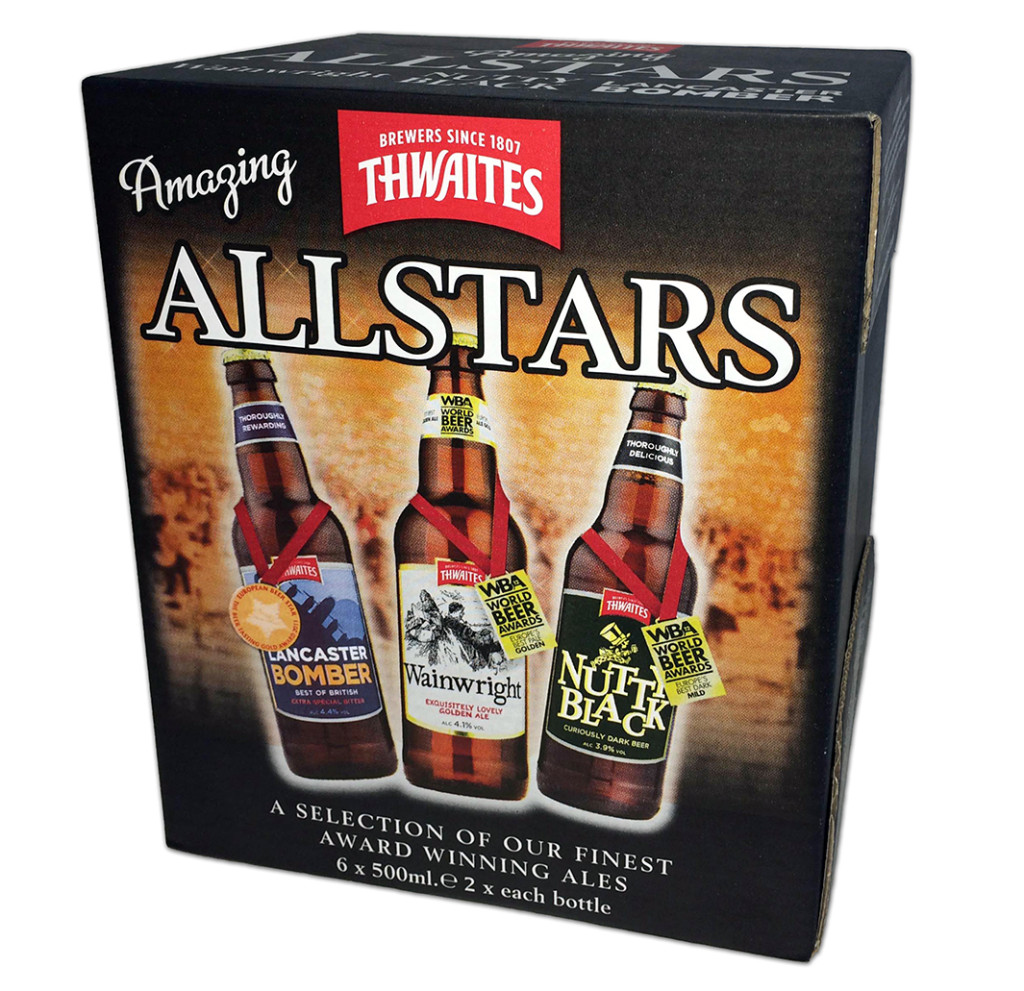

GOLD Post Print on Folder Gluers Uncoated

The artwork was supplied by a Design Agency as a 4 colour process suitable for litho print.

The challenge was to duplicate the litho artwork and convert this to be printed flexo.

All text, logos and the backgound image had to be Repro’d to the machine tolerances, this included Photoshop flexo re-touching of the photographic images including removing unnecessary colour from specific channels, grey component replacement, and minimum dot allowance.

The box was printed 4 colour and die-cut on our Bobst 618 casemaker rotary die cutter at 85 Lpi onto uncoated board in one pass.

GOLD Best Creative Use Of The Flexo Process

SILVER Post Print on Folder Gluers Uncoated

GOLD Best Creative Use Of The Flexo Process

We created a light box from corrugated board showing illuminated Halloween images by using fluorescent inks and LED lights.

The Halloween images were digitally printed onto corrugated board and made into a light box frame. Using our Bobst 618 press, we printed a number of boards in various colours using Fluorescent inks which would illuminate when LED light is used.

The Halloween images on the digitally printed frame were cut using our Zund G3 CAD cutting table. We cut the images from the various fluorescent boards and placed them behind the cut out areas on the frame. LED lights were placed around each image inside the frame to create the completed light box.

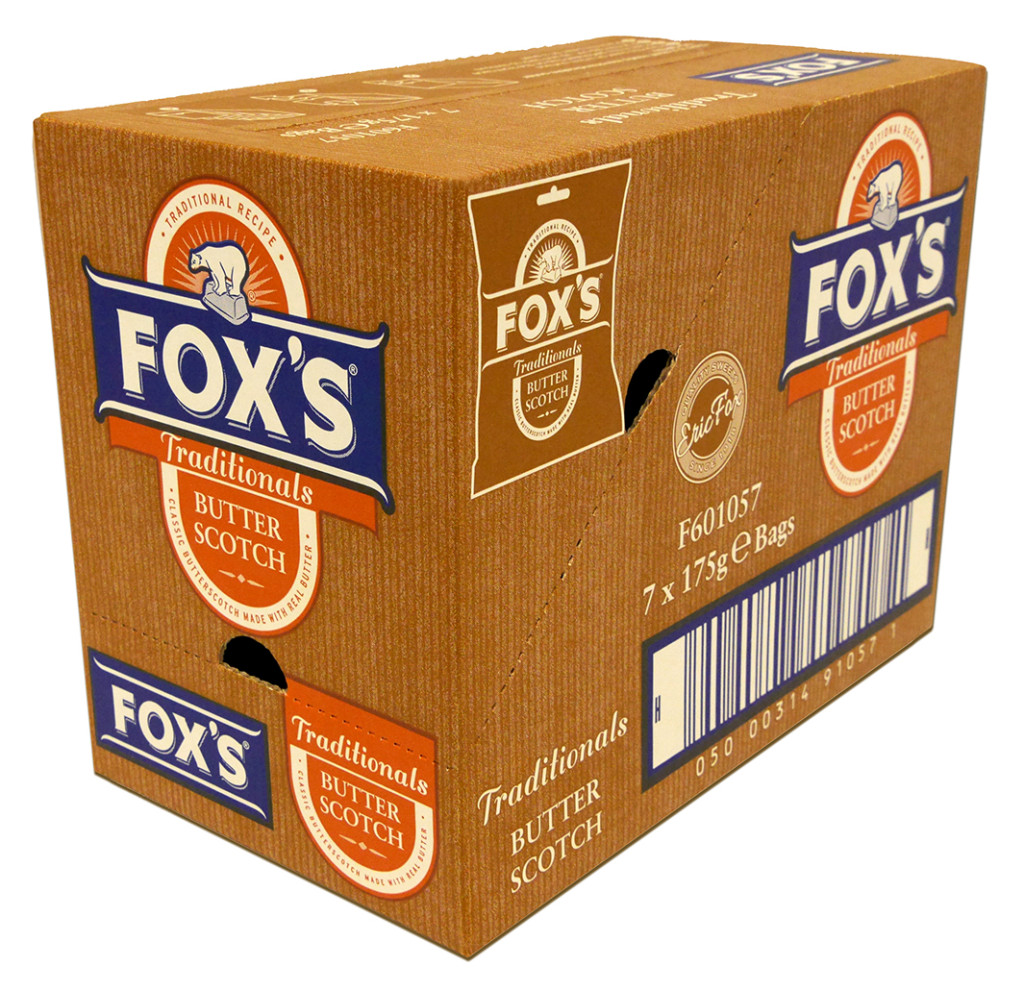

SILVER Post Print on Folder Gluers Uncoated

We were asked to create artwork for an SRP trying to match the same graphics as the product packaging which was printed Litho.

This type of work would normally be produced on larger complex printers which can achieve tight tolerances for registration .

We managed to create the artwork using only three colours, and had to use the minimum tolerances that were achievable on the machine and anilox specification.

The box was printed and die-cut on our Bobst 618 casemaker rotary die cutter at 75 Lpi onto uncoated board in one pass.